This page goes through fabric and layup techniques to determine the best combination to use in the Fablab network. Following round 3 of testing it was decided to continue with Duck canvas material given its low cost and wide availability.

The canvas is available in a range of weights, therefore the first round of experiementation is to see how differently the different weights perform and also determine how many layers are needed.

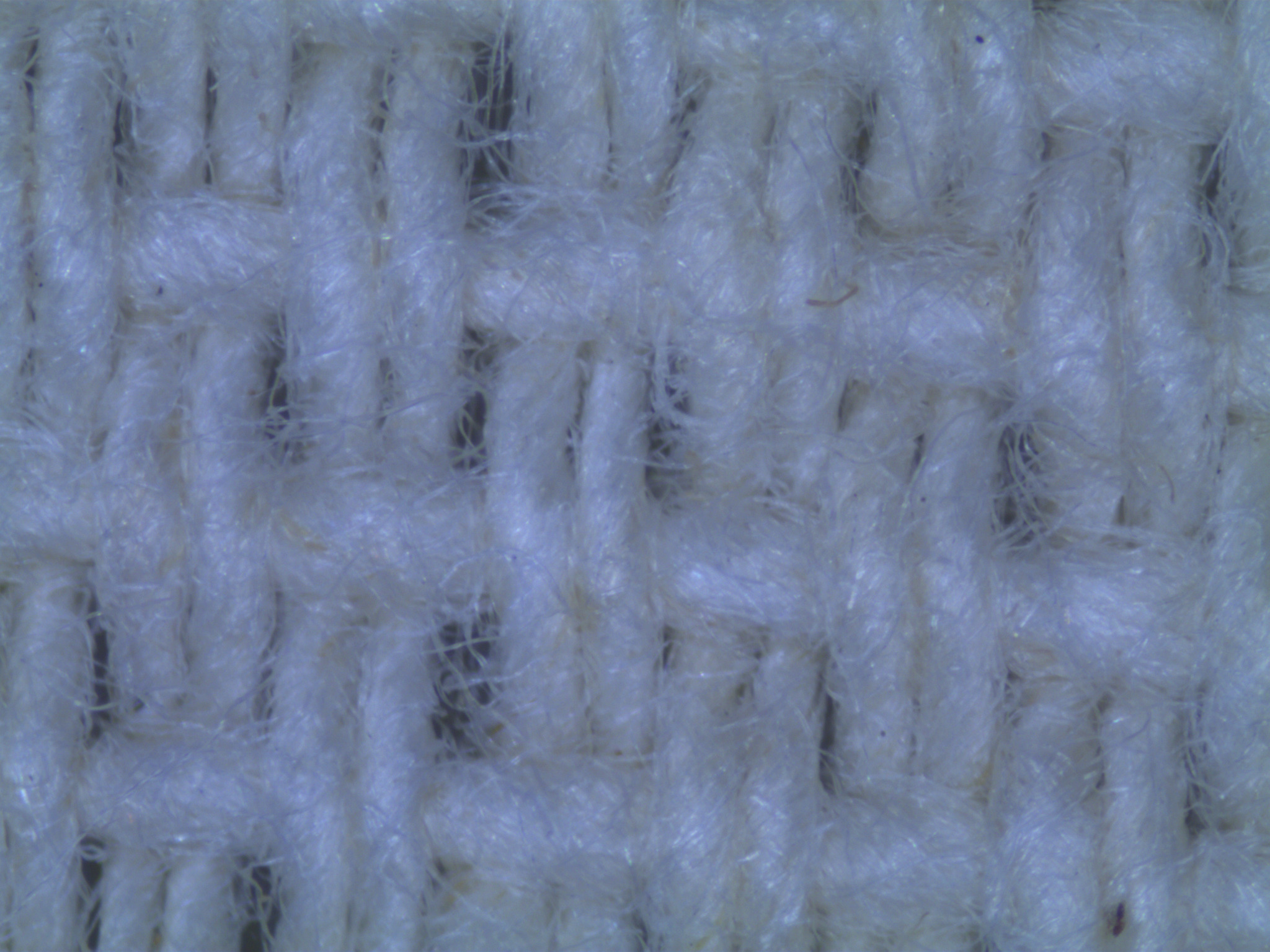

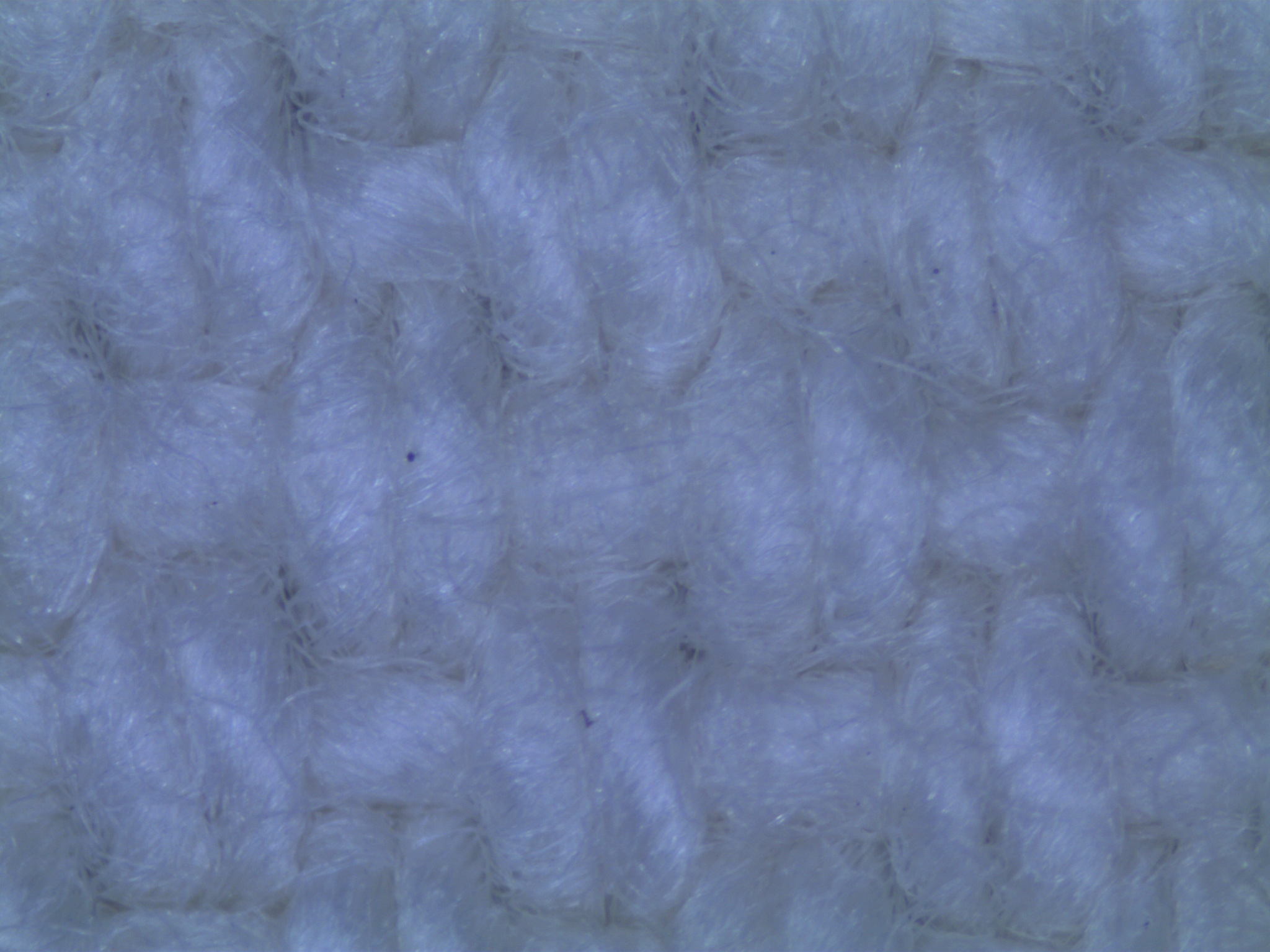

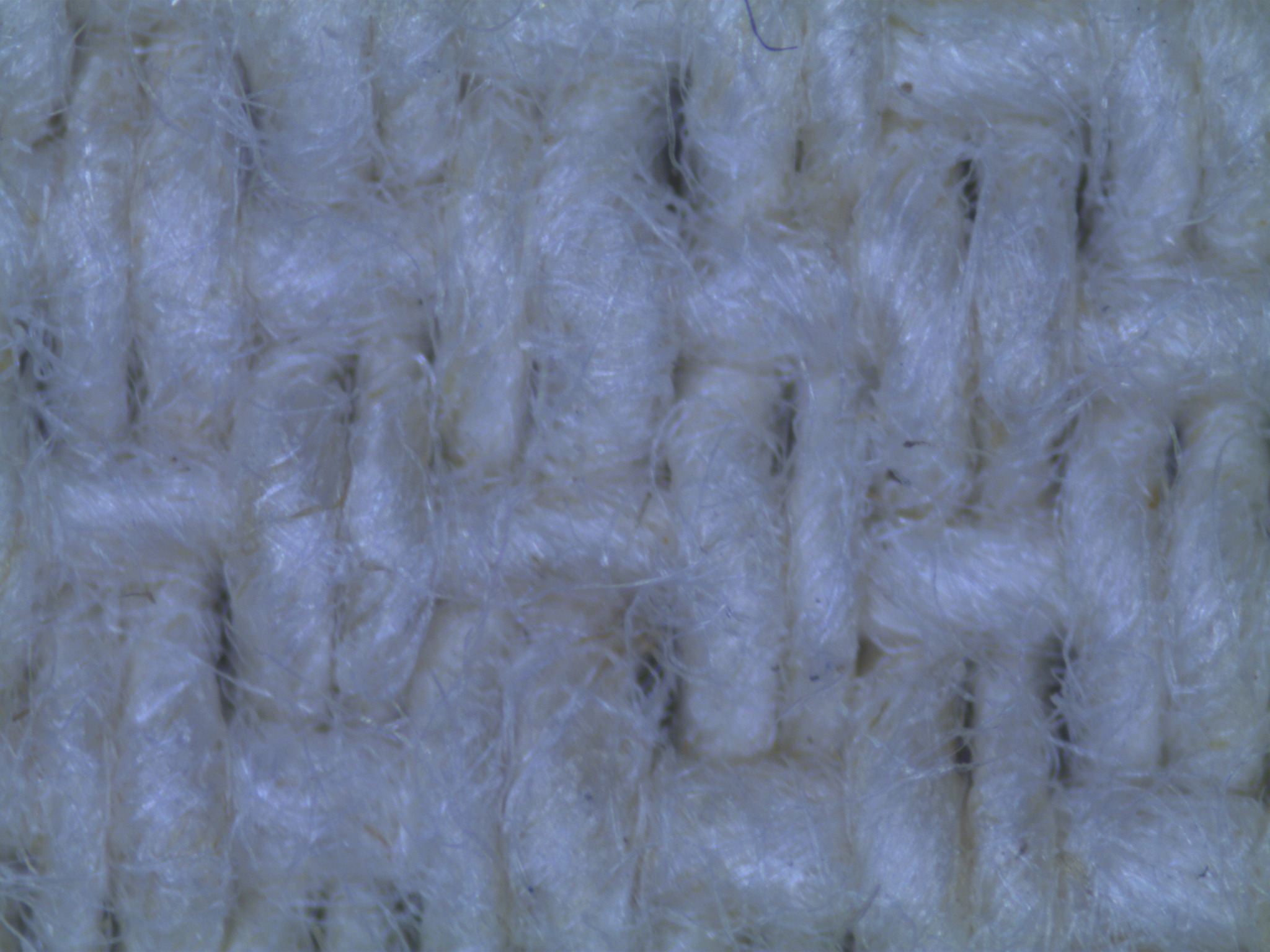

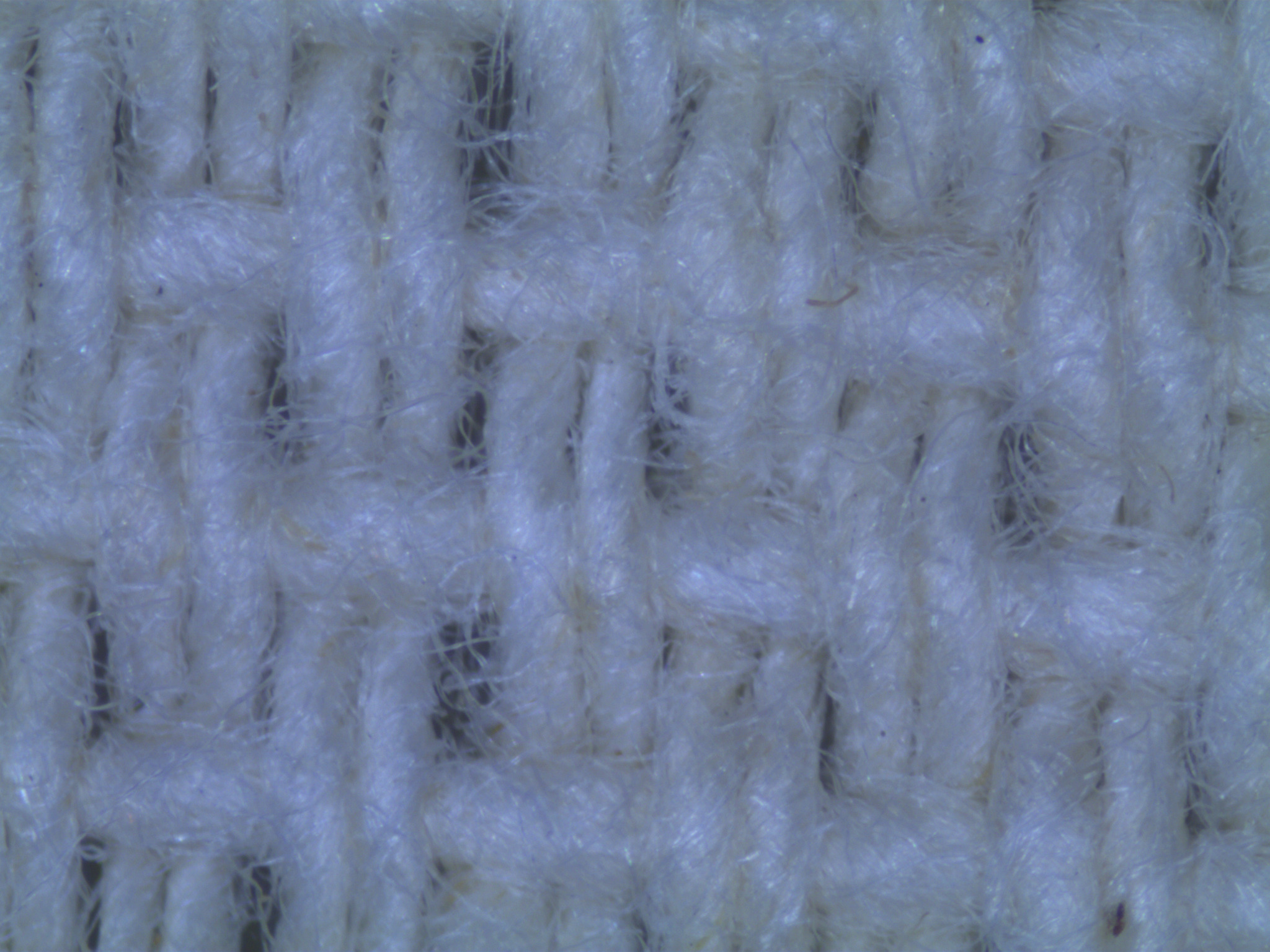

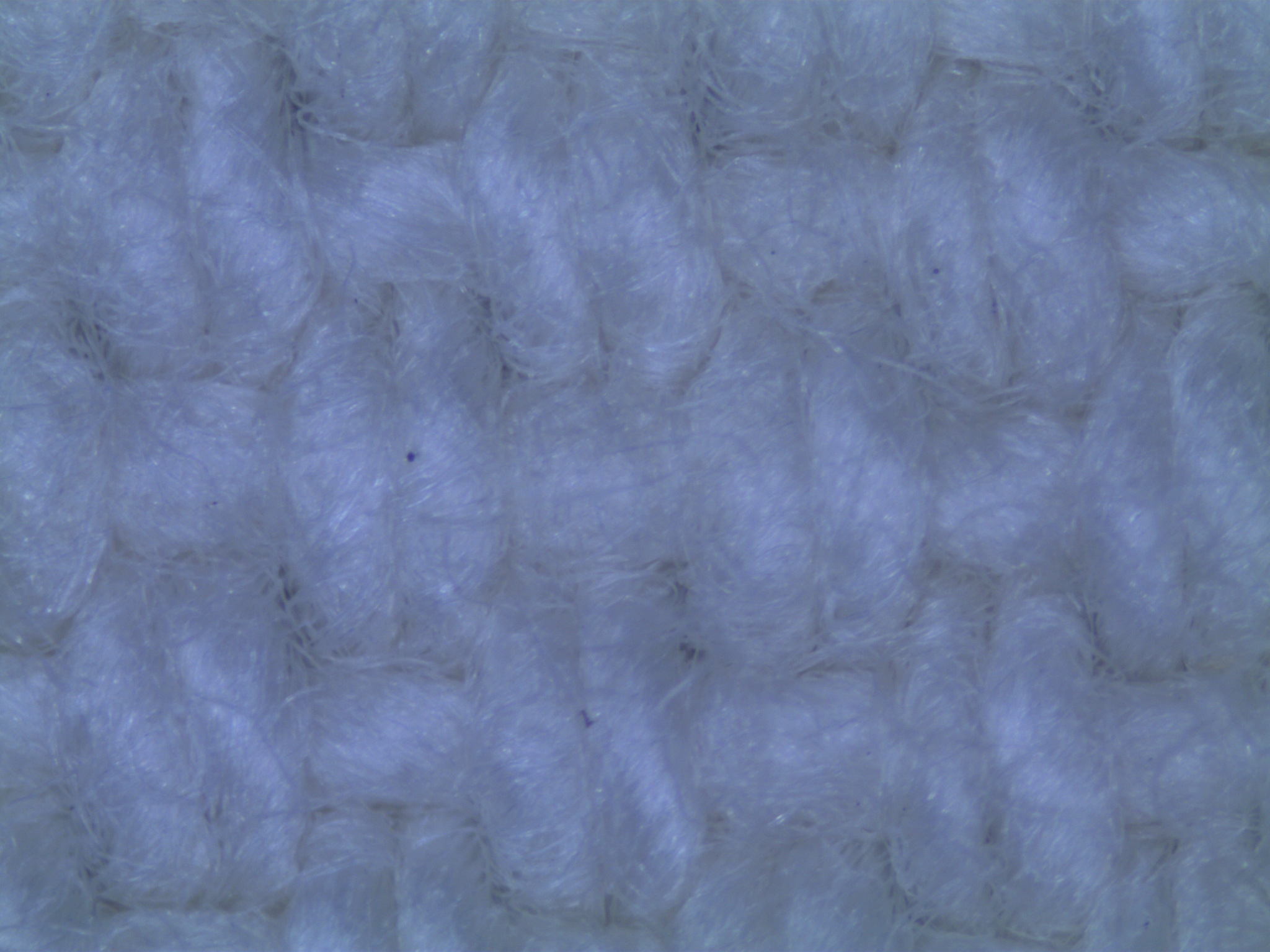

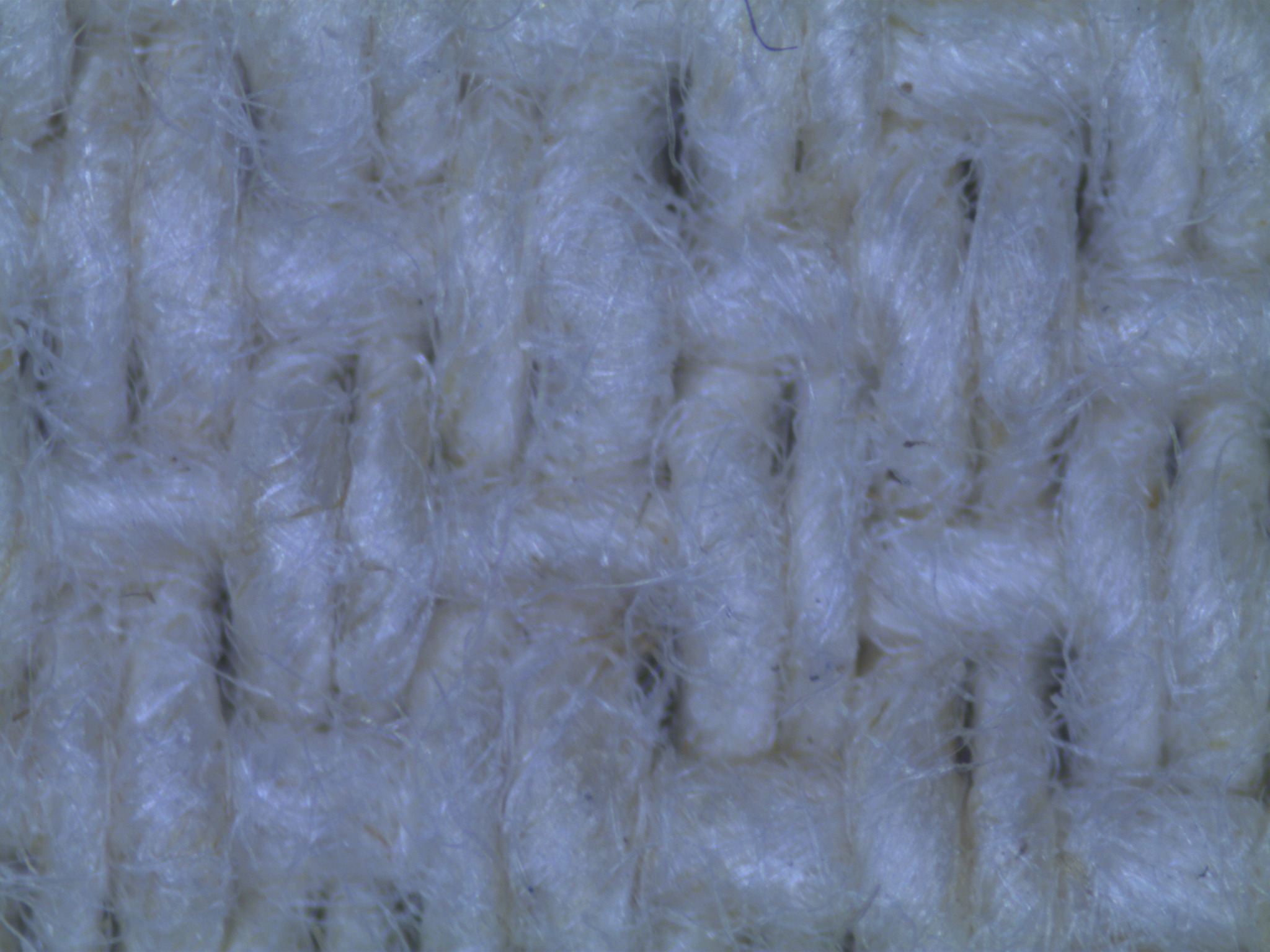

| Weight | 7.3 oz | 9.3 oz | 10 oz | 12 oz |

|---|---|---|---|---|

| Image |  |

|

|

|

| Vendor | Product & Vendor | Product & Vendor | Product & Vendor | Product & Vendor |

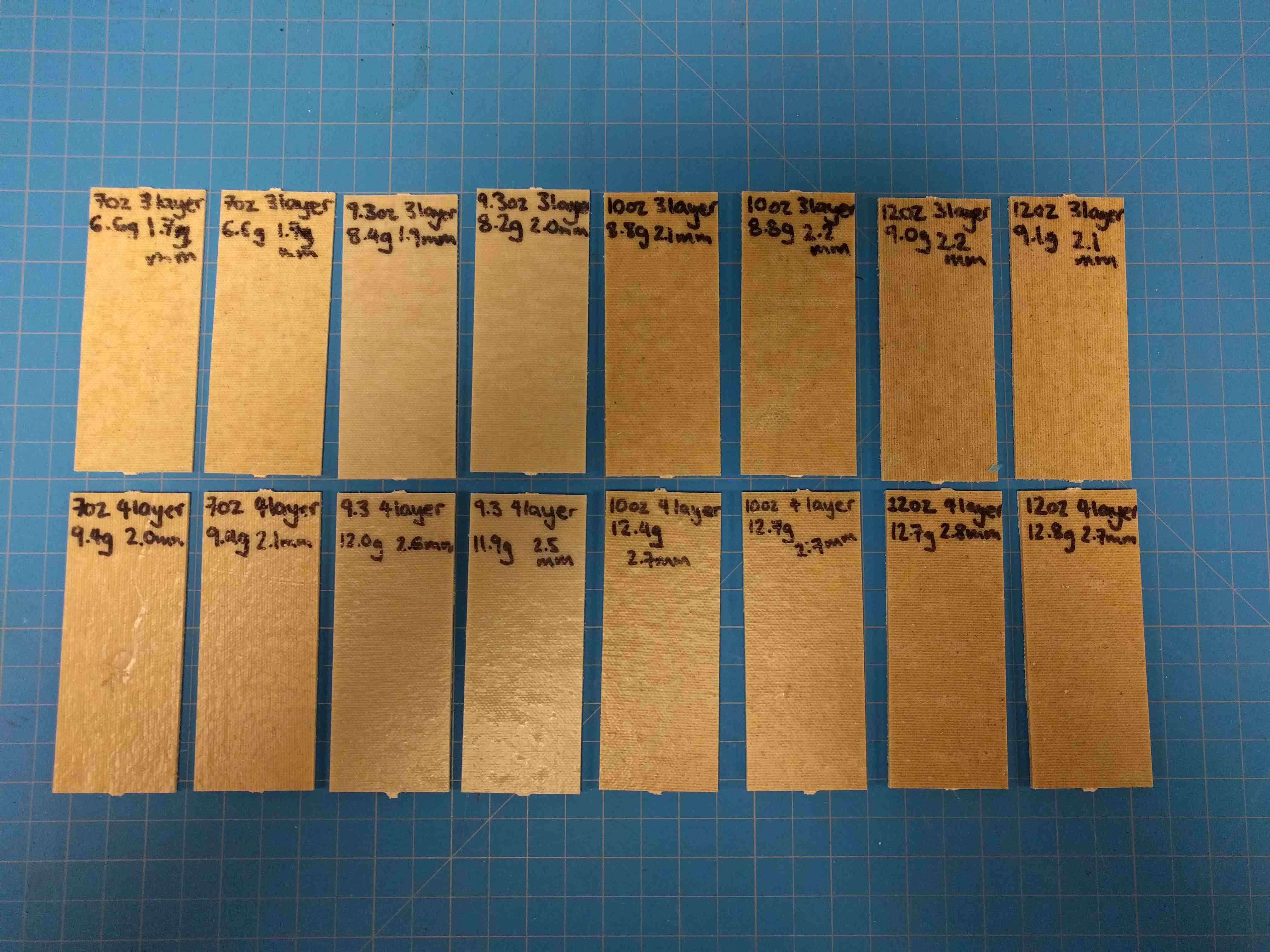

| Mass 4 layer coupons | 9.4g 9.4g | 12.0g 11.9g | 12.4g 12.7g | 12.8g 12.7g |

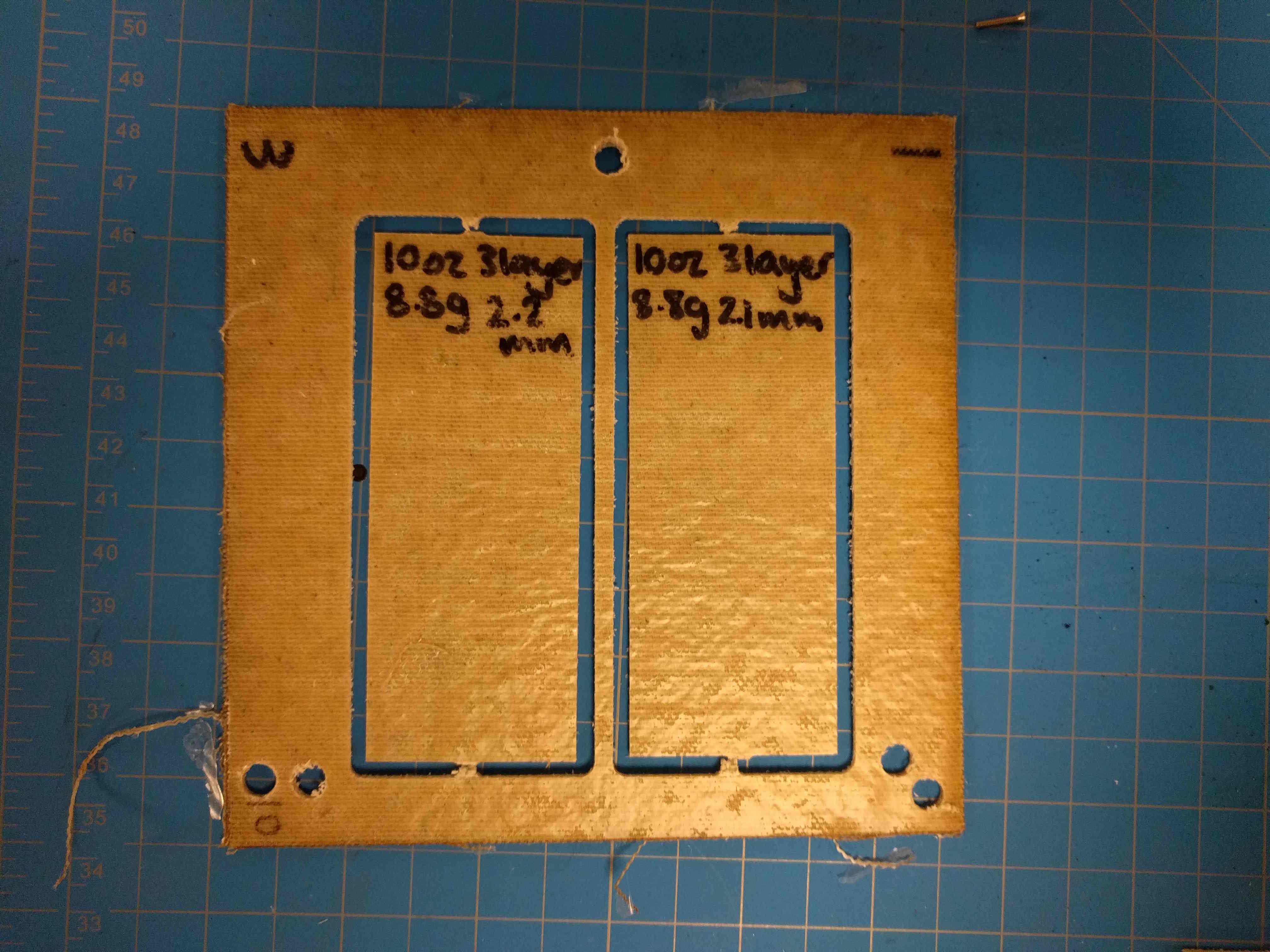

| Mass 3 layer coupon | 6.6g 6.6g | 8.2g 8.4g | 8.8g 8.8g | 9.0g 9.1g |

| Thickness 3 layer coupon | 1.7mm 1.7mm = average 1.7mm | 2.0mm 1.9mm = average 1.95mm | 2.2mm 2.1mm = average 2.15mm | 2.2mm 2.1mm = average 2.15mm |

| Thickness 4 layer coupon | 2.0mm 2.1mm = average 2.05mm | 2.6mm 2.5mm = average 2.65mm | 2.7mm 2.7mm = average 2.7mm | 2.7mm 2.8mm = average 2.75mm |

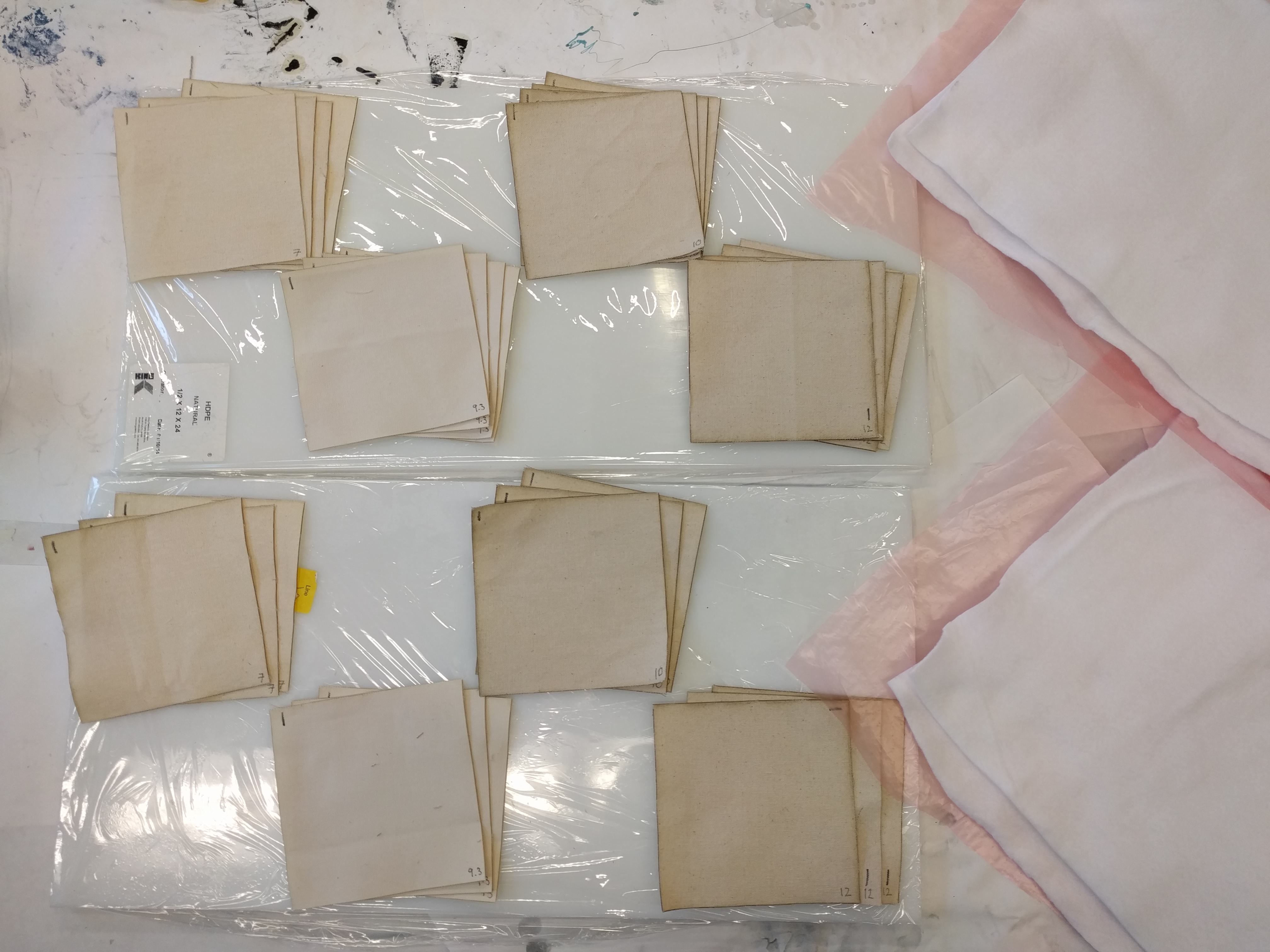

I laid up 2 samples of each material. 1 sample contains 3 layers and the other samples contains 4 layers. I then applied breater and a 2 thin layers of bleeder and pulled out excess epoxy using a vacuum bag. The 3 layer samples weren't fully saturated with epoxy due to some issues with the holes in the bag, despite this we continued to mill samples.

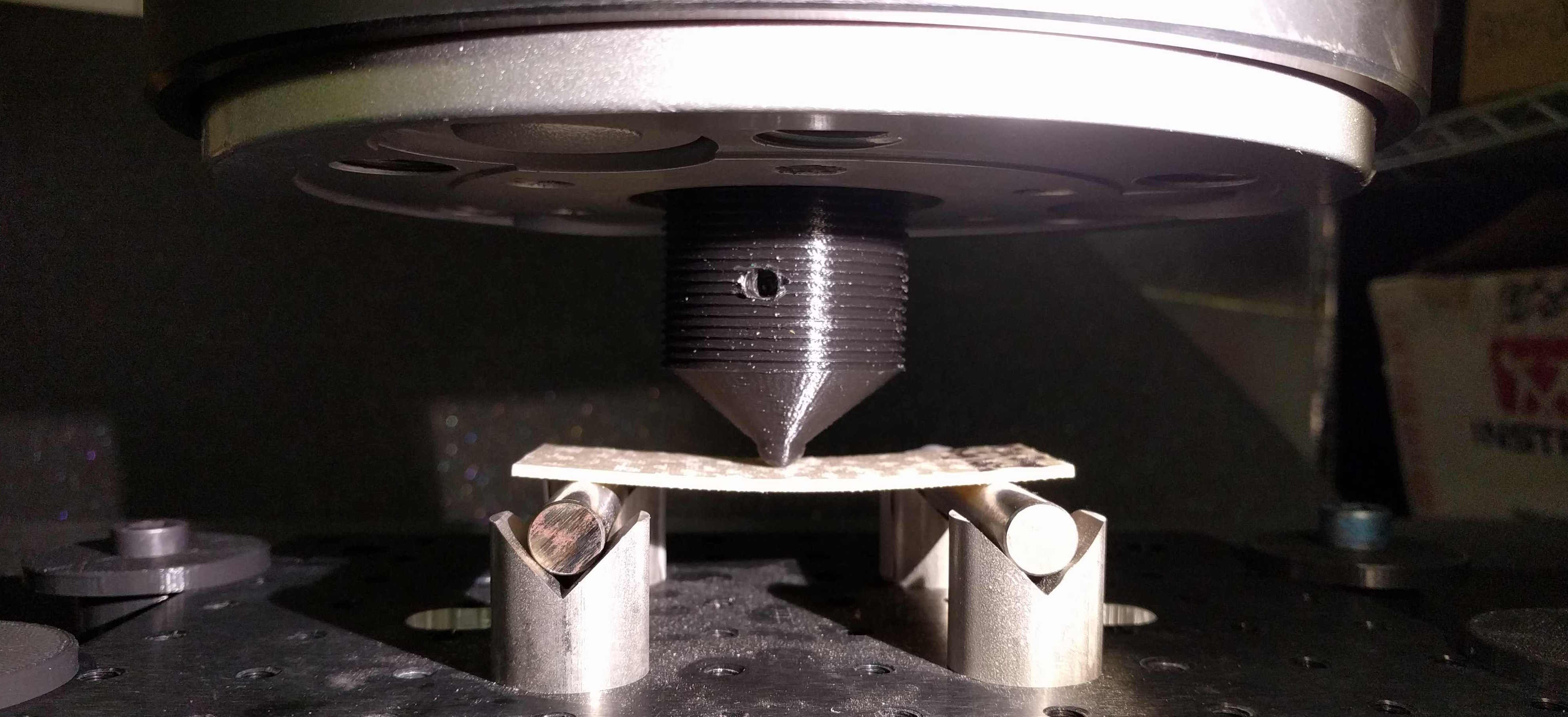

Harith and I milled coupons on the Shopbot using a 1/8", 2 flute, down cut, square end mill.

The same fixturing from round 3 was used for testing in this round. As mentioned previously, the central contact point in the 3 point bending test is 3D printed and therefore introduces a certain amount of compliance into the system however given that we're focused on comparative stiffness testing, this setup is suitable.

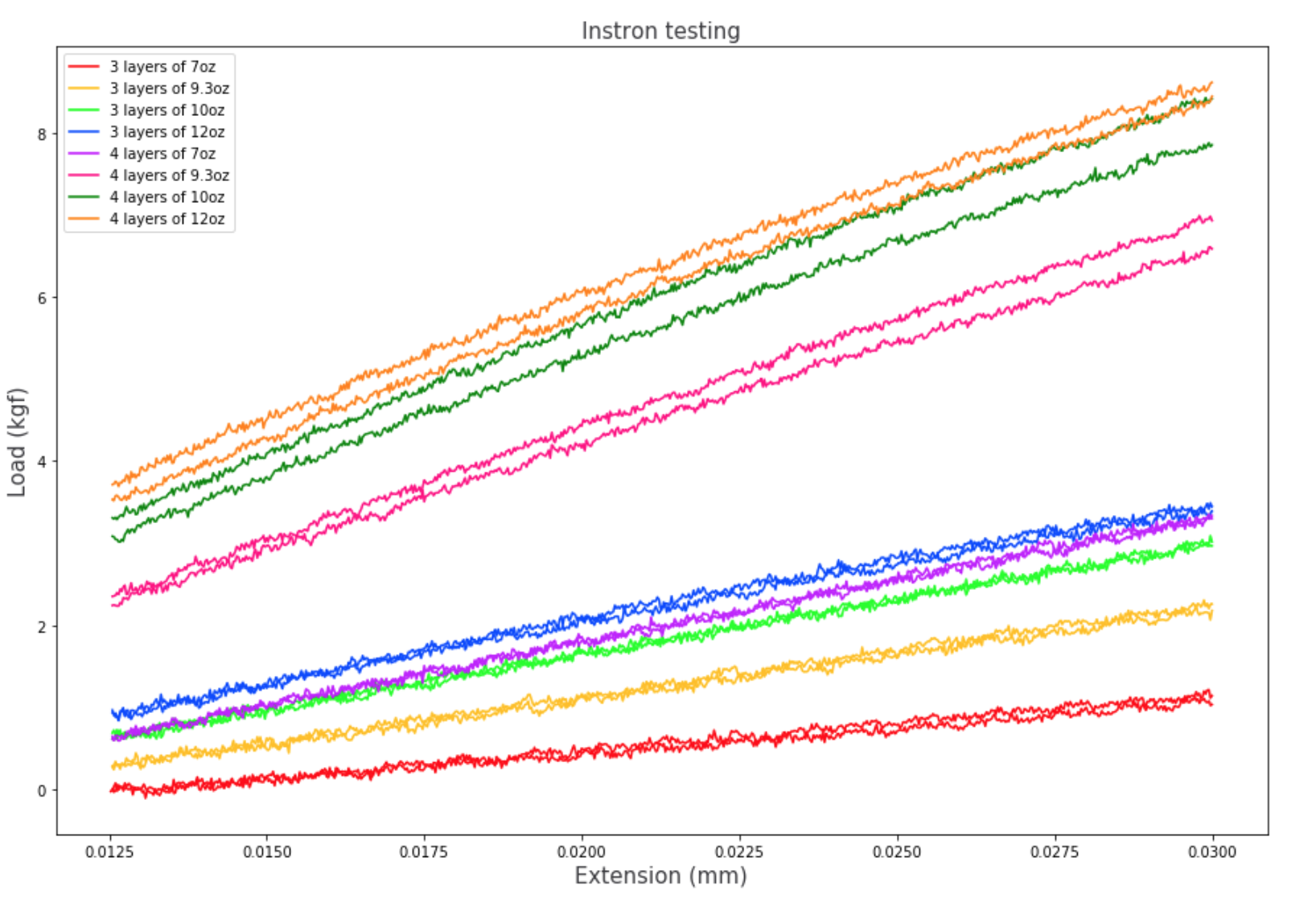

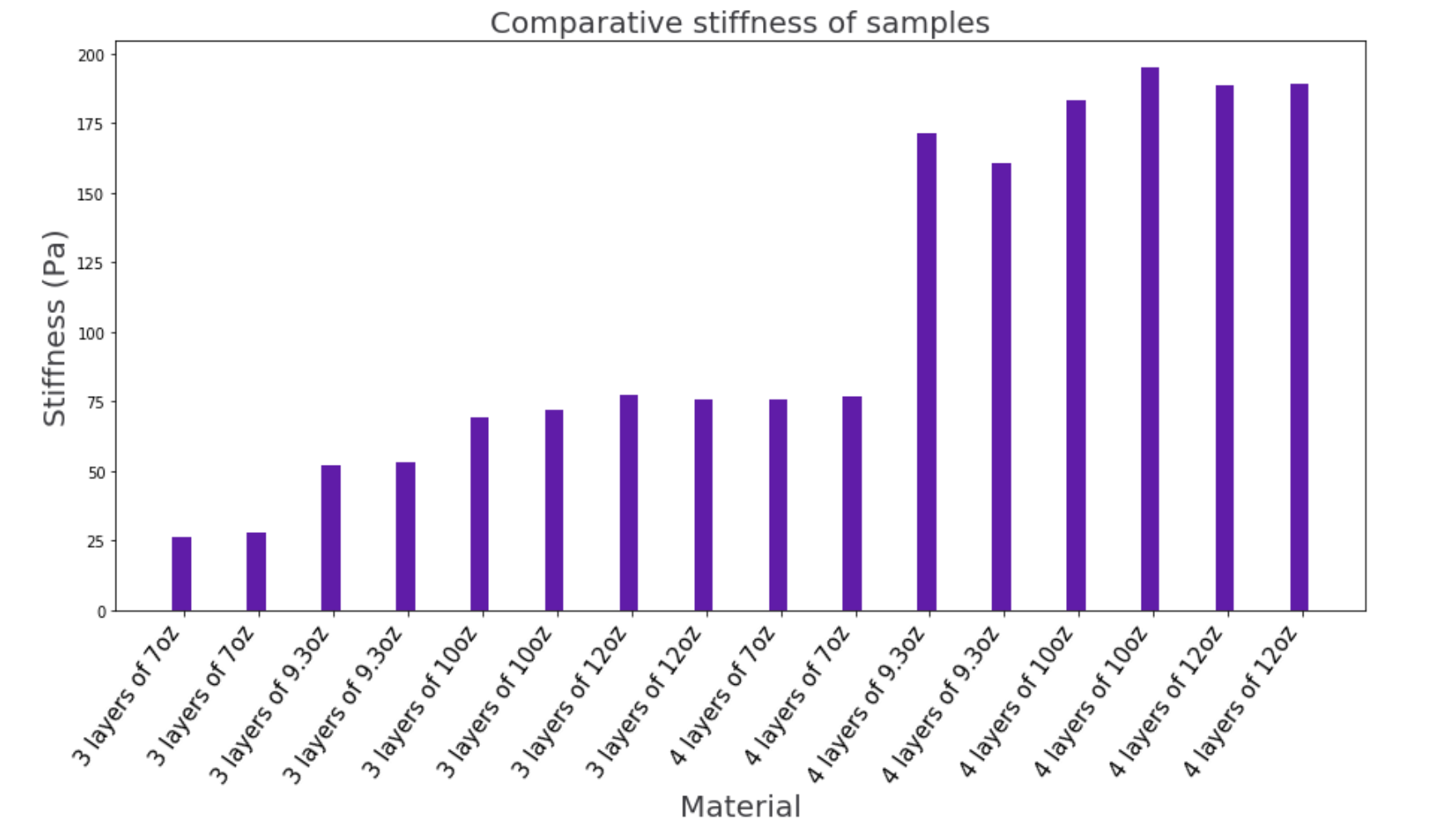

This graph was created in the Jupyer notebook titled coupon_test_round_4.ipynb. It shows that the canvas sample is the stiffest and therefore we'll continue with thicker canvas material.